| www.dcengineering.co.uk - specialist dairy engineers and milking machine installers |

|

Home |

Outdoor

Directory |

DCE services | DCE Products |

Enquiries | Links | Second Hand |

News | DeLaval Parlours |

Weather

|

|

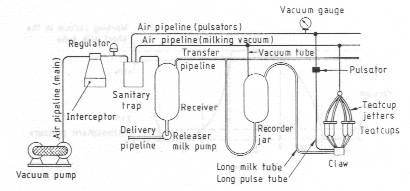

This is by far the most common type of milking machine in use today. It is a very adaptable system which can be fitted into all types of situation. It has many advantages including clearly being able to see how much milk each cow is producing at each milking, you can visually examine the quality of the milk and it is simple to prevent milk with antibiotics or mastitis entering the bulk milk tank.

Each recorder jar holds between 27 and 32 litres (7 and 8 gallons) of milk, which by modern day cow production standards can be to small for the highest yielding cows, which causes the jars to overflow with milk, filling the sanitary trap with milk. (The first recorder jars were 23 litres or 5 gallons, but were soon found to be too small)

With recorder jar milking machines, it is also possible to link them to automatic cluster removers and automatic milk recording systems.

The disadvantage of having a recorder jar milking machine is the

very high surface area, which causes large heat losses during circulation

cleaning making sterilisation difficult to achieve unless you have more than the

recommended amount of water to hand, and creates a large area for bugs to breed

in, giving potential problems to achieve the highest of hygiene standards. The

second problem is that there are so many restrictions between the vacuum supply

and the cluster that it can cause problems of vacuum stability in the cluster,

causing the milking units to creep on the teats, which can cause them to fall on

the floor, or cause damage to the teat ends of the cow.

The disadvantage of having a recorder jar milking machine is the

very high surface area, which causes large heat losses during circulation

cleaning making sterilisation difficult to achieve unless you have more than the

recommended amount of water to hand, and creates a large area for bugs to breed

in, giving potential problems to achieve the highest of hygiene standards. The

second problem is that there are so many restrictions between the vacuum supply

and the cluster that it can cause problems of vacuum stability in the cluster,

causing the milking units to creep on the teats, which can cause them to fall on

the floor, or cause damage to the teat ends of the cow.

A solution for the lower airflow problem is, however, available from De Laval, in the form of the Jar-65 update, which gives a similar airflow to direct to line systems. (65 litres of airflow per minute at the cluster.)

|

|

Copyright dc engineering 1987-2007. All copyrights, trademarks, service marks, and logo's are the respective property of their holders. This site may not be copied without the written consent of dc engineering. All text that is intellectual property is copyrighted. Images and our Logos are copyrighted and may not be reproduced in any way without the written consent of dc engineering. This site is maintained by