| www.dcengineering.co.uk - specialist dairy engineers and milking machine installers |

|

Home |

Outdoor

Directory |

DCE services | DCE Products |

Enquiries | Links | Second Hand |

News | DeLaval Parlours |

Weather

|

|

[also see pulsation terminology]

Before the invention of the modern machine milker, the teats were squeezed and massaged by hand. Obviously a mechanical method had to be reached to copy the action of the hand, and this is how the pulsator was born. The concept was clear to understand, a mechanical method of squeezing the teat was needed. It was not long before we had swinging pendulum type pulsation systems, and a variety of vacuum or vacuum hydraulic systems. It was soon realised just how important accurate pulsation was, both for speed of milking, and the health of the cow, so although the principles of operation are pretty much the same through out, the methods of achieving them have changed considerably over the later years.

As the pulsator operates, it causes the chamber between the teat cup and liner to regularly alternate from vacuum to air source, giving the same effect as squeezing the teat by hand.

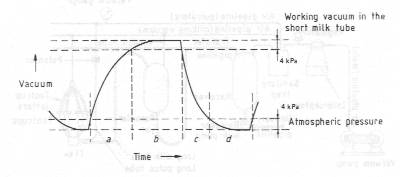

(a) increasing vacuum phase - this brings the liner from atmospheric pressure up to milking vacuum. (opens the liner)

(b) maximum vacuum phase - this keeps the liner at milking vacuum. (keeping the liner open, allowing milk to flow from the cows teat)

(c) decreasing vacuum phase - this fall in vacuum allows the liner to collapse around the teat (beginning of rest phase)

(d) minimum vacuum phase - there is very low vacuum to atmospheric pressure in this phase. The liner is closed around the teat end, and no milk can flow. (massaging the teat)

(a) + (b) are known as the milking phase. It is where the teat is brought from atmospheric pressure up to milking vacuum. Milk flows.

(c) + (d) are known as the rest phase. It is where the teat is brought from milking vacuum down to atmospheric pressure. No milk flows.

[The duration of each phase as a percentage of the total cycle time is measured between the points at which the record of the pulsation chamber intersects abscissae drawn at the working vacuum in the short milk tube minus 4kPa and at a vacuum of 4kPa.]

Pulsators can be either vacuum or electrically operated. The

vacuum operated pulsator uses air to move the plunger or slide valve which opens

and closes the air passages to produce the pulsating action. The plunger or

slide valve may be housed in oil for smoother action. Some pulsators are

adjustable, but mainly are factory set. This type of pulsator is prone to

variations in speed and ratio as temperature change, and can slow down to a

virtual stand still if frozen.

Pulsators can be either vacuum or electrically operated. The

vacuum operated pulsator uses air to move the plunger or slide valve which opens

and closes the air passages to produce the pulsating action. The plunger or

slide valve may be housed in oil for smoother action. Some pulsators are

adjustable, but mainly are factory set. This type of pulsator is prone to

variations in speed and ratio as temperature change, and can slow down to a

virtual stand still if frozen.

The electric pulsator is usually operated by variable electric commands sent from a master controller, allowing it to perform at a preset pulsation rate and ratio. This type of pulsator is generally unaffected by outside influences, and has the ability to perform a more constant pulsation rate.

Some new pulsators have the electronics mounted internally, and work in the same way as electric pulsators, but despite being a lot dearer to purchase, are more economical for smaller installations, as there is no need to buy a master controller.

|

|

Copyright dc engineering 1987-2007. All copyrights, trademarks, service marks, and logo's are the respective property of their holders. This site may not be copied without the written consent of dc engineering. All text that is intellectual property is copyrighted. Images and our Logos are copyrighted and may not be reproduced in any way without the written consent of dc engineering. This site is maintained by